TECHNOLOGIES

Today KRÜTH has three locations in Solingen, where the latest in 3D-Laser-Engraving and Laser-Etching-Engraving are carried out, along with traditional Etching-Engraving. Two further locations, in Austria and Portugal, use classical techniques in production.

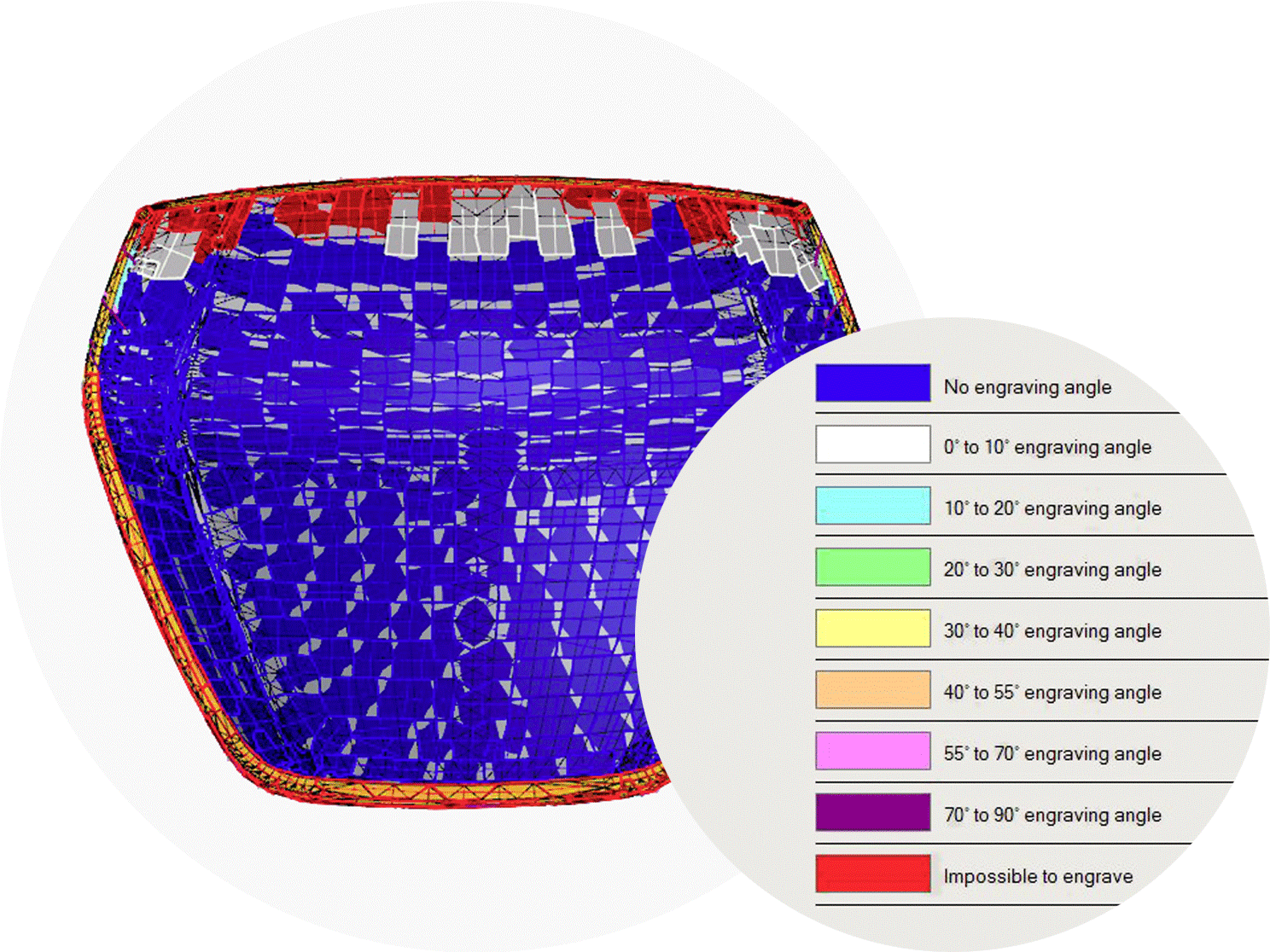

In the conferences that precede this step, all the formal and technical details will have been discussed using parts that have not been yet been structured. Transitions in the engraving and sections with lower relief are specified while taking account of draft angles. Also possible, depending on the technology being used, is evaluating CAD data in advance and conducting feasibility studies to support the process. It is important to satisfy the visual, tactile and acoustic requirements as well as the needs listed in the specifications for the function, always taking account of the technology being used. Another objective is achieving a uniform degree of gloss from one item to the next.